Potassium chlorate, when heated strongly decomposes slowly giving dioxygen. The decomposition occurs in the temperature range of 653-873K.

However, when a little of manganese dioxide is added, the decomposition takes place at a considerably lower temperature range, i.e., 473-633K and also at a much accelerated rate. The added manganese dioxide remains unchanged with respect to its mass and composition. In a similar manner, the rates of a number of chemical reactions can be altered by the mere presence of a foreign substance.The systematic study of the effect of various foreign substances on the rates of chemical reactions was first made by Berzelius, in 1835. He suggested the term catalyst for such substances. Substances, which accelerate the rate of a chemical reaction and themselves remain chemically and quantitatively unchanged after the reaction, are known as catalysts, and the phenomenon is known as catalysis. You have already studied about catalysts and its functioning.

Promoters and poisons

Promoters are substances that enhance the activity of a catalyst while poisons decrease the activity of a catalyst. For example, in Haber’s process for manufacture of ammonia, molybdenum acts as a promoter for iron which is used as a catalyst.

Catalysis can be broadly divided into two groups:

(a) Homogeneous catalysis,

(b) Heterogeneous catalysis.

(a) Homogeneous catalysis: When the reactants and the catalyst are in the same phase (i.e., liquid or gas), the process is said to be homogeneous catalysis. The following are some of the examples of homogeneous catalysis:

(i) Oxidation of sulphur dioxide into sulphur trioxide with dioxygen in the presence of oxides of nitrogen as the catalyst in the lead chamber process.

The reactants, sulphur dioxide and oxygen, and the catalyst, nitric oxide, are all in the same phase.

(ii) Hydrolysis of methyl acetate is catalysed by H+ ions furnished by hydrochloric acid.

Both the reactants and the catalyst are in the same phase.

(iii) Hydrolysis of sugar is catalysed by H+ ions furnished by sulphuric acid.

(b) Heterogeneous catalysis:The catalytic process in which the reactants and the catalyst are in different phases is known as heterogeneous catalysis. Some of the examples of heterogeneous catalysis are given below:

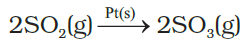

(i) Oxidation of sulphur dioxide into sulphur trioxide in the presence of Pt.

The reactant is in gaseous state while the catalyst is in the solid state.

(ii) Combination between dinitrogen and dihydrogen to form ammonia in the presence of finely divided iron in Haber’s process.

The reactants are in gaseous state while the catalyst is in the solid state.

(iii) Oxidation of ammonia into nitric oxide in the presence of platinum gauze in Ostwald’s process.

The reactants are in gaseous state while the catalyst is in the solid state.

(iv) Hydrogenation of vegetable oils in the presence of finely divided nickel as catalyst.

One of the reactants is in liquid state and the other in gaseous state while the catalyst is in the solid state.

(b) Selectivity

The selectivity of a catalyst is its ability to direct a reaction to yield a particular product. For example, starting with H2 and CO, and using different catalysts, we get different products.

The catalytic reaction that depends upon the pore structure of the catalyst and the size of the reactant and product molecules is called shape-selective catalysis. Zeolites are good shape-selective catalysts

The catalytic reaction that depends upon the pore structure of the catalyst and the size of the reactant and product molecules is called shape-selective catalysis. Zeolites are good shape-selective catalysts

because of their honeycomb-like structures. They are microporous aluminosilicates with three dimensional network of silicates in which some silicon atoms are replaced by aluminium atoms giving Al–O–Si framework. The reactions taking place in zeolites depend upon the size and shape of reactant and product molecules as well as upon the pores and cavities of the zeolites. They are found in nature as well as synthesised for catalytic selectivity. Zeolites are being very widely used as catalysts in petrochemical industries for cracking of hydrocarbons and isomerisation. An important zeolite catalyst used in the petroleum industry is ZSM-5. It converts alcohols directly into gasoline (petrol) by dehydrating them to give a mixture of hydrocarbons.

However, when a little of manganese dioxide is added, the decomposition takes place at a considerably lower temperature range, i.e., 473-633K and also at a much accelerated rate. The added manganese dioxide remains unchanged with respect to its mass and composition. In a similar manner, the rates of a number of chemical reactions can be altered by the mere presence of a foreign substance.The systematic study of the effect of various foreign substances on the rates of chemical reactions was first made by Berzelius, in 1835. He suggested the term catalyst for such substances. Substances, which accelerate the rate of a chemical reaction and themselves remain chemically and quantitatively unchanged after the reaction, are known as catalysts, and the phenomenon is known as catalysis. You have already studied about catalysts and its functioning.

Promoters and poisons

Promoters are substances that enhance the activity of a catalyst while poisons decrease the activity of a catalyst. For example, in Haber’s process for manufacture of ammonia, molybdenum acts as a promoter for iron which is used as a catalyst.

Catalysis can be broadly divided into two groups:

(a) Homogeneous catalysis,

(b) Heterogeneous catalysis.

(a) Homogeneous catalysis: When the reactants and the catalyst are in the same phase (i.e., liquid or gas), the process is said to be homogeneous catalysis. The following are some of the examples of homogeneous catalysis:

(i) Oxidation of sulphur dioxide into sulphur trioxide with dioxygen in the presence of oxides of nitrogen as the catalyst in the lead chamber process.

The reactants, sulphur dioxide and oxygen, and the catalyst, nitric oxide, are all in the same phase.

(ii) Hydrolysis of methyl acetate is catalysed by H+ ions furnished by hydrochloric acid.

Both the reactants and the catalyst are in the same phase.

(iii) Hydrolysis of sugar is catalysed by H+ ions furnished by sulphuric acid.

(b) Heterogeneous catalysis:The catalytic process in which the reactants and the catalyst are in different phases is known as heterogeneous catalysis. Some of the examples of heterogeneous catalysis are given below:

(i) Oxidation of sulphur dioxide into sulphur trioxide in the presence of Pt.

The reactant is in gaseous state while the catalyst is in the solid state.

(ii) Combination between dinitrogen and dihydrogen to form ammonia in the presence of finely divided iron in Haber’s process.

The reactants are in gaseous state while the catalyst is in the solid state.

(iii) Oxidation of ammonia into nitric oxide in the presence of platinum gauze in Ostwald’s process.

The reactants are in gaseous state while the catalyst is in the solid state.

(iv) Hydrogenation of vegetable oils in the presence of finely divided nickel as catalyst.

One of the reactants is in liquid state and the other in gaseous state while the catalyst is in the solid state.

Adsorption Theory of Heterogeneous Catalysis

This theory explains the mechanism of heterogeneous catalysis. The old theory, known as adsorption theory of catalysis, was that the reactants in gaseous state or in solutions, are adsorbed

on the surface of the solid catalyst. The increase in concentration of the reactants on the surface increases the rate of reaction. Adsorption being an exothermic process, the heat of adsorption is utilised in enhancing the rate of the reaction. The catalytic action can be explained in terms of the intermediate compound formation.

on the surface of the solid catalyst. The increase in concentration of the reactants on the surface increases the rate of reaction. Adsorption being an exothermic process, the heat of adsorption is utilised in enhancing the rate of the reaction. The catalytic action can be explained in terms of the intermediate compound formation.

The modern adsorption theory is the combination of intermediate compound formation theory and the old adsorption theory. The catalytic activity is localised on the surface of the catalyst. The mechanism involves five steps:

(i) Diffusion of reactants to the surface of the catalyst.

(ii) Adsorption of reactant molecules on the surface of the catalyst.

(iii) Occurrence of chemical reaction on the catalyst’s surface through formation of an intermediate.

(iv) Desorption of reaction products from the catalyst surface, and thereby making the surface available again for more reaction to occur.

(v) Diffusion of reaction products away from the catalyst’s surface. The surface of the catalyst unlike the inner part of the bulk, has free valencies which provide the seat for chemical forces of

attraction. When a gas comes in contact with such a surface, its molecules are held up there due to loose chemical combination. If different molecules are adsorbed side by side, they may react with

each other resulting in the formation of new molecules. Thus, formed molecules may evaporate leaving the surface for the fresh reactant molecules.

This theory explains why the catalyst remains unchanged in mass and chemical composition at the end of the reaction and is effective.

(i) Diffusion of reactants to the surface of the catalyst.

(ii) Adsorption of reactant molecules on the surface of the catalyst.

(iii) Occurrence of chemical reaction on the catalyst’s surface through formation of an intermediate.

(iv) Desorption of reaction products from the catalyst surface, and thereby making the surface available again for more reaction to occur.

(v) Diffusion of reaction products away from the catalyst’s surface. The surface of the catalyst unlike the inner part of the bulk, has free valencies which provide the seat for chemical forces of

attraction. When a gas comes in contact with such a surface, its molecules are held up there due to loose chemical combination. If different molecules are adsorbed side by side, they may react with

each other resulting in the formation of new molecules. Thus, formed molecules may evaporate leaving the surface for the fresh reactant molecules.

This theory explains why the catalyst remains unchanged in mass and chemical composition at the end of the reaction and is effective.

Important features of solid catalysts(a) Activity

The activity of a catalyst depends upon the strength of chemisorption to a large extent. The reactants must get adsorbed reasonably strongly on to the catalyst to become active. However, they must not get adsorbed so strongly that they are immobilised and other reactants are left with no space on the catalyst’s surface for adsorption. It has been found that for hydrogenation reaction, the

catalytic activity increases from Group 5 to Group 11 metals with maximum activity being shown by groups 7-9 elements of the periodic table.

catalytic activity increases from Group 5 to Group 11 metals with maximum activity being shown by groups 7-9 elements of the periodic table.

(b) Selectivity

The selectivity of a catalyst is its ability to direct a reaction to yield a particular product. For example, starting with H2 and CO, and using different catalysts, we get different products.

Thus, it can be inferred that the action of a catalyst is highly selective in nature, i.e., a given substance can act as a catalyst only in a particular reaction and not for all the reactions. It means that a substance which acts as a catalyst in one reaction may fail to catalyse another reaction.

Shape Selective Catalysis by Zeolite

The catalytic reaction that depends upon the pore structure of the catalyst and the size of the reactant and product molecules is called shape-selective catalysis. Zeolites are good shape-selective catalysts

The catalytic reaction that depends upon the pore structure of the catalyst and the size of the reactant and product molecules is called shape-selective catalysis. Zeolites are good shape-selective catalystsbecause of their honeycomb-like structures. They are microporous aluminosilicates with three dimensional network of silicates in which some silicon atoms are replaced by aluminium atoms giving Al–O–Si framework. The reactions taking place in zeolites depend upon the size and shape of reactant and product molecules as well as upon the pores and cavities of the zeolites. They are found in nature as well as synthesised for catalytic selectivity. Zeolites are being very widely used as catalysts in petrochemical industries for cracking of hydrocarbons and isomerisation. An important zeolite catalyst used in the petroleum industry is ZSM-5. It converts alcohols directly into gasoline (petrol) by dehydrating them to give a mixture of hydrocarbons.

0 comments:

Post a Comment